When people search for “laser cut foam”, they’re often looking for precision foam inserts designed to fit specific tools, equipment, or products.

However, you’ll be surprised that, most of the time, laser cut foam, well, doesn’t use a laser. In fact, it’s usually produced using a CNC machine.

What is “Laser Cut Foam”?

Laser cut foam is generally referred to as CNC-cut foam, so it’s cut using a CNC (Computer Numerical Control) machine. These machines use specialised routers (or water jets) instead of lasers, resulting in a clean finish. They can also be programmed to cut specific shapes to ensure precision and to remove human error.

Types of Foam Cutting

CNC-cut foam is the primary type of precision foam cutting. However, there’s also another type: laser etching.

CNC Cut Foam

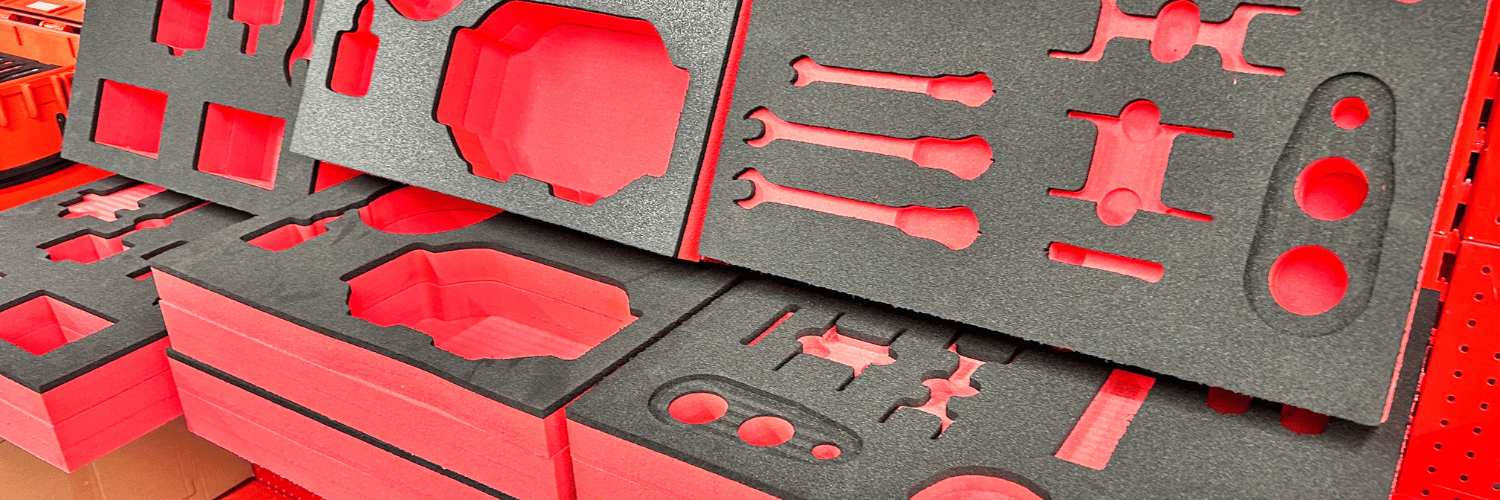

Many people call CNC-cut foam “laser cut foam” without realising it. The process involves cutting the foam using a computer-controlled router, blade, or waterjet to carve out specific shapes in the material. It is also digitally programmed and based on a digital design file.

Generally, this is the most sought-after type of foam cutting. It’s ideal for creating foam pieces varying in depth and shapes, so it’s commonly used for foam packing inserts, tool protection, shadow boards, etc.

Key Benefits

- High Precision: CNC machines are digitally programmed, ensuring optimal precision and consistent quality.

- Great Versatility: This process is suitable for a range of foam-cutting needs and industries, including foam case inserts, display foam, and more.

- Mass Production Capability: CNC cut foam can also be mass produced, so it’s ideal for anyone looking for a bulk order.

Laser Foam Etching

Laser etching uses a focused laser beam to heat the foam’s surface. This process removes a very thin layer of material that creates shallow marks or designs.

In most cases, the laser cutting foam technique is used for adding logos, text, part numbers, or patterns to a foam surface.

Key Benefits

- Intricate Designs: Can be used to add fine details to foam, such as logos, text, part numbers, etc.

- Non-Invasive Process: It can alter the surface of the foam without affecting the structural integrity of the material.

- Durability of Markings: Laser-etching foam is much more durable than other printed methods like silk screening.

Comparing Different Foam Cutting Techniques

Feature | CNC-Cut Foam | Laser Etched Foam |

|---|---|---|

What It Is | Foam cut using a CNC router, blade, or waterjet, often referred to as “laser cut” foam

| Uses a focused laser beam to remove a thin surface layer, creating shallow designs

|

Depth Control | Multi-depth cuts

| Surface-level only

|

Precision

| High

| Very High

|

Applications | Packaging inserts, shadow boards, tool protection

| Logos, text, part numbers

|

Durability of Results

| High | Moderate

|

Customisation Flexibility

| High | High

|

Key Benefits | – Digitally programmed for precision – Versatile for many industries – Suitable for mass production | – Enables intricate designs – Doesn’t affect foam’s structure – More durable than printed methods |

When to Use CNC Cutting vs. Laser Etching

Choosing between CNC cutting and laser etching depends on your applications. However, we’d suggest the following.

Use CNC Cutting when you need foam to hold or protect items. Think custom tool inserts, equipment cases, shadow boards, multi-layer packaging solutions, etc.

Regarding laser etching, use it when you want to add surface-level detail to the foam. For example, adding a logo or branding, marking part or item numbers, or creating visual instructions or identifiers.

In some cases, the best solution combines them both. Together, for instance, you can create a tool shadow board that displays tool identification.

Conclusion

As you can see, “CNC-cut foam” is usually referred to as “laser cut foam”. However, there is another method called laser etching.

The best option for you depends on your foam-cutting needs. For help deciding which option is more suited for your application, feel free to contact a Red Box Foam representative today.